Archive

At the Panel Shop – UPDATE 27th August 2012

UPDATE – 27th August 2012

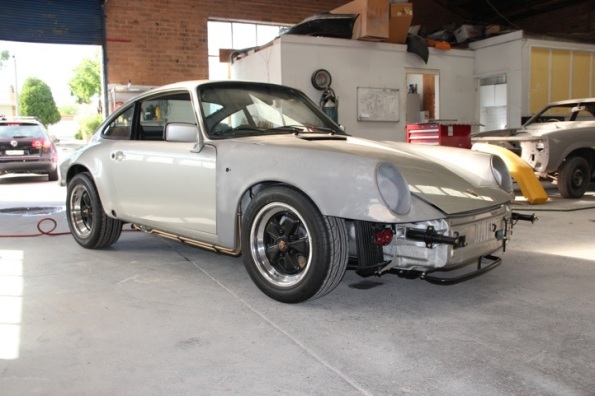

A fair of time has passed since the last update. I was away for 3 weeks plus a few other distractions got in the way. Car is back and I have just finished the assembly. Just needs the engine. Here’s the pics.

UPDATE – 29th May 2012

Here’s some pics fresh out of the oven. The original plan was to rub back to ‘glass’ but the job is so nice off the gun we are going to leave it. It actually looks a bit more natural with a slight bit of the peel. More pics when I start to get it assembled.

UPDATE – 25th May 2012

It’s coming along now with top coat due any day. The following pics show some of the prep. At this stage car has been rubbed back with some areas taken back to metal – as there was way too much product from previous ‘touch ups’. There was so much on there that the paint was cracking in spots, especially under the rain gutters. It’s all been sorted now and the car is virtually ready for primer filler. These guys are working fast now!

Good news is that nothing nasty has been uncovered, just the excess product which has been rectified.

UPDATE – 17th May 2012

First update in about a month but there has been plenty going on in the interim – I’ve just been lazy updating the blog. There’s changes with the bodywork, engine, transmission and interior but I’ll post updates separately. For now it’s the body work.

The car currently sits awaiting a final coat of primer-filler and then the whole car will be rubbed back and then colour coated. Colour is probably about 2 weeks away. Here’s some pics but I’ve added a bit more text after the images.

To date the guards have been prepped. I ended up replacing the RHD front guard as the origianl had some rust and rather then attempt a repair it was easier and more cost effective to replace it. I also replaced the rear bumper for the same reason.

The cracking in paintwork around the rain gutters was a result of too much pain on previous repairs. This area was brought back to metal and it was discovered that the car had more than one previous paint job. It appears that each owner had a go at making the car look as good as new. The end result was too much paint and so the rub down will sort this out – this has partly caused a delay longer than expected. I’m confident with Frank who is doing the job, he knows I want a top job and he is working accordingly. We’ve discussed how he will paint the panels and the end result is that the jambs will be done and then the entire car painted with panels attached – this came from consultation with his sprayman and the fact the car is silver metallic.

Other minor points are that the areas that scared me the most were the sills – but they are OK. I had some polished sill guards and I suspected they were covering up some nasty surprise. This wasn’t the case which was a huge relief. When the car goes back together I’m putting the factory black rubber ones on – less bling and more class in my opinion.

UPDATE – 12th April 2012

Dropped in the collect the window trim which will be powder coated, along with the door handles and other external trim work. I was a little worried what it would look like with the windows out, in particular potential rust around the front windscreen. The was also a spot at the top of the driver side rear window but this is fine. A bit of cleaning back and it will be good. Not really worth pics but I thought I’d add these.

The car is now in the hands of Frank, who is going to fix up all the small blemishes and give the car a full respray. The pics make the car look good already butplenty are small issues I want fixed. Door jambs are rough (previous respray), rear quarters need to be reblocked, couple of small runs, some chips, a couple of small parking dents, and refinished lower panels all add up to the full respray.

Some before pics -after spending a couple of hours removing doors and mirrors.

Exterior Paint – The Unplanned Project….

With so many ‘while you’re in there’ projects going on I have finally surrendered to getting the exterior redone. It’s not that it’s bad or actually really ‘needs’ doing but it was always on the car and it seems like a more efficient time to do it. I had stripped back all the lower panels as they were a bit worse for wear so they needed painting anyway. The dilema I had was with colour matching, especially for a metallic silver.

The colour of the car as it is does not match the formula colour provided by the local Glasurit supplier. This is what I had purchased for the wheel wells, engine bay and front boot. I knew it was off but as the exterior was to be painted at some point I wasn’t concerned. I then had some paint colour matched for the lower panels (fender extension, valance’s, bumpers).

When I thought about it it didn’t seem to make sense to paint it, only to strip it back and repaint again sometime in the next year or 2. With this I contacted a local paint guy who I’ve done some other work for and he came over for a look. A couple of days later he’d prepared a quote based on rub back and paint but also included gapping the panels. I would be responsible for dressing up the bumpers with trim and putting back all the lower panels. No problem..

The quote was very agreeable and so it’s booked in. The car will be in mid March and hopefully ready mid April. I contacted the mechanic and he said the motor and trans will be done about then so the timing is good.

When it’s all done, it should be pretty much a full resto – with a paint job I can love! Here’s pics of the stripped and etch primed panels. They’ve since had Wurth SKS on the right parts so nothing more for me to do – just get them to the painter. I’ll be stripping the bumpers and rear lid hinges but that’s about it.

Project – Underbody and Wheel Wheels – Updated 8th March 2011

UPDATE – 8th MARCH 2011

At last – painting is done and I’m ready to reassemble. Realistically I still have some other smaller parts to paint and refinish but nearly all of it is done. Today I’m picking up a replacement crossmember so this will enable me to start putting the front end back together. All that stuff stored in boxes can finally make it’s way back to the car.

To be honest I was a bit nervous about painting in case there were issues. The Glasurit product is excellent and it was really quite easy to do. I certainly wouldn’t tackle the exterior but for what I am doing it turned out well.

UPDATE – 11th JANUARY 2011

It’s a bit scary when I see that my most recent update on this project is almost 4 months ago. Lots of other things to do kept me away from the car. Anyway, I had applied the Wurth SKS in December but had a problem with the batch – it was right on its Use By date and it didn’t dry properly, instead remaining tacky. I almost shot some new stuff over the top but it just didn’t seem like the right path to take. Instead I rubbed it all back and applied new product. The result is really pleasing.

Glasurit paint has been ordered and even though it is about triple the expected price I am looking forward to seeing the colour on the wheel wheels. I still have to repair the front bumper shock but I’ll get some colour on the rears first. This way the area is sealed and I can start assembling while I wait for “Mr Welder” to come by and weave his magic. I ain’t gonna weld this myself – some things I just won’t tackle.

Anyway, some pics.

UPDATE – 19th SEPTEMBER 2010

It’s been a while since an update on this project. Having been away and also only really getting a couple of hours here and there it was impossible to progress as quickly as I would have liked. Over the last couple of weeks I have finished cleaning/prepping and masked up ready for chip guard (Wurth SKS).

Today I setup up the SKS gun for the first time and after a few practice sprays I started on the car. I was surprised how easy it was apply. I am really pleased with how it has come up. I feel liked I really moved forward after doing this. Here are some pics.

Back to metal for the area around seal and where SKS is not applied. This was etch primed just after this pic.

SKS done – not much applied at bumper shock mount as this is going to be replaced with a not so rusty one

UPDATE – 25th JULY 2010

I’ve been feeling that progress is going very slowly. Today I wanted to get some sense of achievement so I polished up the front half of the brass oil lines – came up quite well. Ideally it would be media blasted but I am not going that far on this project!

Also brushed back the RHS bumper shock mount and coated with POR15. This pic was taken before the Metal Ready which really cleaned up alot of the surface rust. I am hoping that the POR15 process works as claimed – if so I’ll never need to touch this area again!

Here it is with POR15

And with Upol Acid 8

UPDATE – 23rd JULY 2010

Pics to come after this weekend but both fenders are off. Drive side (RHS) is a bit messy and will be replaced when I eventually do a respray. Not worrying about it for the moment as it’s not part of this project. So far the project status is:

- Remove suspension and brakes – done

- Send parts for blasting and recoating as relevant – done (not yet back, expected mid August)

- Repair underbody – partly completed

- Clean wheel wells – partly completed

When suspension coems back I will get the car rolling again and them off to a mates place where he is going to cut rust and weld new metal. He’ll do the brakes and then the car will come back for final SKS and paint then assembly.

UPDATE – 5th JULY 2010

Almost everything off now. Only got the RHS front fender to go which is requiring a bit of careful consideration. One of the PO’s had attempted to fix/hide some rust and in doing so bogged the fender to the sill!! I think one day I will have to strip the driver sill back to bare metal for a 100% understanding of what is going on – but not now. I have to draw the line and going this far breached my rule of ‘no DIY on the exterior body’, valances and rocker panels excepted. Luckily the bogged area is under the rocker panel so I didn’t feel too bad pulling out the cutting wheel and dremel. As I was cutting I was feeling a bit ickky but it needs to be done.

The LHS fender came off pretty easily and I know it’s been off before as there was no weather seal there. I started on the scrubbing, using my 3M pad – making sure not to destroy the existing rubber undercoat. I simply want to clean and prep well enough to prime so no need to take it all off. The integrity is pretty good so I am pretty happy. Taking the panels off makes it so much easier, plus I can get into all the awkward spots. The added bonus is that I will KNOW what the situation is on every part of the car.

Finally got all the suspension, steering and brake components out. When I say finally I really took my time partly because I wasn’t sure how far I was going to go with this. In the end I don’t want to have to do this twice so I may as well do it properly. Nothing on the car is going to be a patch job.

I also say ‘finally’ because some of these components were and absolute ‘biatch’ to get out. The worst was probably the spring plates. Something I should be talking about on the suspension project but still worth noting here. I tried for a week to get these things off the torsion bars and it was looking doubtful. Read more at the suspension project post.

Anyway, it was a great relief to have everything removed and packed away. In a couple of weeks I’ll have a spare Saturday morning to head down to Autocoupe where Phil is going to blast some bits some bits. I’ll recoat some of the parts (ie, sway bars, a arms), leave some others (ie. trailing arms, front cross member) and replate some other bits including hardware. He is also going to rebuild the calipers properly. This means blasting, splitting, re plating and then baking. I am only capable of blasting and new seals so this one is for Phil. Not sure what that will cost???? Hopefully I don’t pass out when he hands me the invoice.

While this is happening I am going to clean/degrease 27 years of grime. I will then ‘spot repair’ any surface rust but cleaning up with wire brush, coat with POR15 to stop any growth, spray rubberised undercoat and then some light passes of body colour. I have researched this process and this so far seems the right way to go. In my opinion is seems like the best approach short of completely stripping. The overall condition is excellent and so I see no need to go that far. I hear alot of complaints about rust in UK cars but I am yet to see anything too scary. All ‘brown’ metal is surface only and will clean off without any hassle. Everything structural is sound. If I see any rust I grab my screwdriver and stab around and so far so good. When I thoroughly clean each area the final truth will be revealed but at this stage I am sleeping easy!!

Probably the worst looking on the pics is where the trailing arm bolts onto the tub. This truely is no issue – only light surface rust that will clean right up. Although this spot is in the engine bay ‘zone’, an area I will tackle when the engine is out, I am going to sort this now ans I don’t want to remove the trailing arm again. It will take me longer to do that later than to fix it now.

In terms of painting I have decided to buy spray equipment and do it as a 2 part paint. It’s likely I will get some solvents on thhe wheel wells or undebody and I really don’t want the paint to discolour. I have read a few threads on pelican parts bodywork forum and this seems like the right way to go. How can it not? It’s how it was done in the factory. Getting a spray gun will allow me to do the rocker panels, front and rear valance as well as front boot refurb. I’m sure I’ll get some other uses out of it.

Enough blogging for now. As I always say, can’t wait to get some after shots of this.

- Prepped and masked

- Prepped and masked

- More shots of prepped and masked – hoping the SKS evens it out…

- Alot of messy and tedious work to get to this point

- Hours and hours here

- That light is like the one at the end of the tunnel!

- Before the grinder hits the metal

- Grinding begins – love the safety procedures!

- Cut out – note the inner sheet metal is retained for a neater finish – thanks Steve!

- Welded on

- Finished – bar one more coat of SKS

- Before hitting the rubbish bin

- Rust protection done

- Before

- After